Project

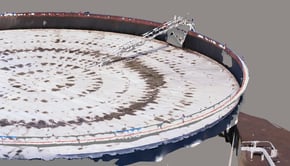

Crude oil and oil products used in the petroleum industry are generally stored in vertical steel cylindrical tanks with flat bottoms. To enable adequate reduction of vapor losses for various types of oil, tanks are divided into two types: fixed-roof tanks and floating-roof tanks. A fixed roof tank consists of cone- or dome-shaped overlapping roof steel plates that rest on a supporting framework and attach to the tank only at the top of the shell. The tanks are usually fully welded, while older tanks often have a riveted or bolted construction. To manage the upkeep of the tanks, inspectors would visit and manually document corrosion and deformities. Laser scans were also utilized, but those could only get a clear image of the tank sides. For a full tank inspection, the rooftop needed to be modelled as well. Falcker used photogrammetry and 2D drawings to build a model of the roof, then overlay images on top of the model to periodically check the status of the seal. Falcker has modeled 200 tanks to date, and expects to build 200 more models in the coming year.

Solutions

First, Falcker used drones to fly over each tank and take overlapping photos. Then using ContextCapture and ContextCapture SDK, Falcker used those photos and the laser scans of the tank sides, to create engineering-ready point clouds and an accurate 3D model.

Facts

- Crude oil and oil products are generally stored in vertical steel cylindrical tanks. Often these tanks have fixed-roofs consisting of cone- or dome-shaped overlapping steel plates that are welded together and cannot be easily inspected – either manually or via laser images.

- Falcker was able to create a 3D model of each tank by using ContextCapture to blend drone images of the rooftop plates together with laser images of the sides.

- ContextCapture SDK helped modelers improve workflow 20x by creating a programmatic solution in ContextCapture.

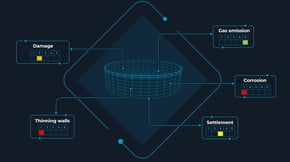

Digitalization of Inspection

Falcker helps organizations reduce risks using reality modeling to inspect assets, making them more reliable and efficient.

Reality Model of Tank

Using ContextCapture's SDK, Falcker generated accurate 3D reality models of the tanks.

Outcome

Previously, it took the modelers at Falcker days to complete the roof alone, because there were only drawings available. Manual readjustments had to be made based on visually overlaying aerial images over the model. This failed to provide accurate results but was usable for inspection purposes. However, the process was extremely time-consuming as it required continuous back and forth between the modelers and the inspectors to adjust roof plates to their correct position and orientation.

To improve the process, Falcker used ContextCapture to process a single tank through the ContextCapture user interface, which obtained much better results. They then sped up the process by using ContextCapture’s SDK to generate 10 – 30 tanks in one session, saving days of work from start to finish without any additional labor, and the results are far more accurate as they rely on 3D data instead of 2D. Falcker estimates they’ve saved at least 24-hours of time for the past 200 tanks – or nearly $13K in labor costs.

Software

Falcker produced a 3D reality model with ContextCapture and leveraged ContextCapture’s SDK, a software development kit that allows programmatic access to all the features of ContextCapture Master. This module acts in the place of the user interface for full project creation, edition and monitoring, and ContextCapture SDK helped Falcker process the drone-captured images to create a realistic 3D model of each oil tank rooftop.

Video: Digitalization and Automation of Tank Inspection with Falcker

Join our Reality Modeling Community to stay up-to-date with the latest news and events: https://www.linkedin.com/showcase/reality-modeling-community

Milo Buwalda

Data Specialist, Falcker