When I’m asked the above question, my usual answer is, “Why do you want to flush?” You can’t figure out how to flush water mains until you understand why you’re doing it.

One of the next questions is, “Should I use conventional or unidirectional flushing (UDF)?”

One of the next questions is, “Should I use conventional or unidirectional flushing (UDF)?”

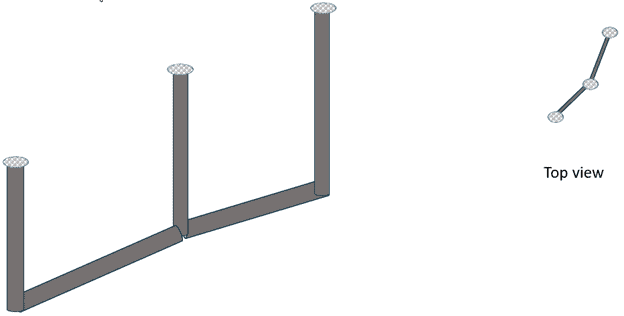

Once again, the answer is, “Why are you flushing.” (For the purpose of this blog, conventional flushing consists of opening a fire hydrant and letting it flow,” while UDF consists of opening one or more hydrants while closing valves to ensure that the flushing will follow a specific path and produce greater velocity.”)

There are a lot of reasons for flushing, which can range from simply ensuring that the hydrant will operate, to showing neighbors that you are actually doing something in response to their water quality complaints, to using flushing as a chance to update values for available fire. Three of the most common are:

- Scour solids from the bottom of pipes

- Move higher quality water into an area

- Remove contamination from a system

Each has different goals and procedures.

Scour solids from the bottom of pipes

Scouring solids involves producing sufficient tractive stress to suspend and move the solids. Tractive stress is sometimes referred to as tractive force although it has units of force per unit area in the direction of flow (which is stress). It is calculated as

Where = tractive stress, (lb/ft2, N/m2), = specific weight of water, (lb/ft3, n/m3), hydraulic radius (ft, m), S = channel slope.

Since most engineers and operators do not have a good feel for tractive stress, many use a scouring velocity as a surrogate, although this is not as theoretically sound. Operators can understand velocity better. The problem is determining the target velocity for effective flushing. Numbers like 3, 5, 7, and 10 ft/sec have been discussed as potential targets.

A possible way to determine the scouring velocity for the solids in your system is to conduct a test. The steps would be: 1. Close a valve to create unidirectional flow, 2. Open a hydrant at the downstream end (to achieve about 3 ft/sec) and flow until the water is clear. 3. Increase the flow and see if additional solids are stirred up, 4. Keep increasing the flow until no more solids are produced and the pipe can be considered clean. You will want to feed this test section by pipes that are clean so that the solids are being stirred up from the test pipe and not arising from upstream pipes.

While the above approach will tell you what maximum velocity you may need, it doesn’t tell you the minimum. The solids in the pipe are those that will settle when the tractive stress (i.e. velocity) is less than the normal day maximum velocity. This may be 1 ft/sec for some mains. In that case, flowing at 2 ft/sec may be adequate. You can determine the maximum daily velocity by running an extended period simulation (EPS) for a typical day and noting the highest velocity. It may be surprisingly low.

The next question is whether UDF is needed. A simple way to do this in WaterGEMS is to run conventional flushing for the hydrants of interest. If the run shows that target velocity is reached without UDF, there is no need for UDF, which takes more time for both planning and execution and requires larger crews.

Move higher quality water into an area

Another reason for flushing is to improve disinfectant residuals. (Water Age is often used as a surrogate for disinfectant concentrations.) Run the EPS model for a very long time to determine the lowest values for disinfectant (highest water age). Save these results and use them for the initial conditions for your flushing run. Then pick hydrants to move the high-quality water into the area of interest. Color coding is a great way to watch fresh water move into an area, displacing the poor-quality water. This can demonstrate if it will take minutes or hours to achieve target concentrations.

The tractive stress makes little difference in this type of flushing unless you are reaching tractive stresses that are just high enough to stir up solids without moving them out of the system. UDF may not be needed for this type of system.

The model can show flow patterns during this time. What is the correct order for flushes? It’s important to remember Gangemi’s law, “Always flush with clean water behind you.”

Remove contamination from a system

This is similar to case 2 above, but the problem here is that there is no accurate way to determine the size and concentration of the contaminant plume at the time when flushing is to start. There may be a few points where the concentration is known, and the concentration between these points can be interpolated. It is important to flush, not where the plume is now, but where it will be when the crew gets to it. During a contamination event, frequent, extensive sampling will be occurring. This enables the modeler to get more precise estimates of plume location to keep the model in calibration with what is happening that day.

If the exact location and quantity of chemical that was drawn into the system is known, then it is possible to do some precise modeling. Uncertainty, in the input leads to uncertainty in the results. In general, flushing should be conducted in the pressure zone or district metered area where the concentration is found. Steps should be taken to prevent movement into other pressure zones or DMAs, such as turning off pumps or closing control valves between zones.

If the contaminant is sufficiently toxic, it may be necessary to take steps to minimize its spread, even after it lease the water distribution system.

WaterGEMS can be an effective tool to help plan a good flushing program.

Want to learn more from our resident water and wastewater expert? Join the Dr. Tom Walski Newsletter today!

One of the next questions is, “Should I use conventional or unidirectional flushing (UDF)?”

One of the next questions is, “Should I use conventional or unidirectional flushing (UDF)?”