Virtuosity Blog

What Happens When the Power Drops Out?

Power outages don’t happen often in developed countries, but they do happen. Pump stations are fed by the power grid, so when the power goes out, it also goes out for water pumping stations. And water utilities don’t like their systems losing pressure.

The usual solution is elevated storage. With elevated storage (including ground storage on a hill), unless the outage is very long, water from storage tanks will keep the system pressurized and most customers will not even notice that the pump station is down.

But there are a lot of pressure zones out there that don’t have elevated storage or an emergency connection with a higher-pressure zone that has storage or pumps with power. These dead-end zones usually have a backup gas or diesel generator, and increasingly these days, solar and batteries that will start when power is lost.

Based on that, you would think there is no problem when power is lost. Not quite. Pumps fed by backup generators don’t reach full speed instantly. First, the control system needs to detect that power is indeed off for a certain duration. Next, it needs to issue a signal to start the generator which takes a few seconds. Then the pump needs to receive a signal to start and come up to speed, and finally, a control valve may also need to slowly open. All this happens fairly quickly, but not instantaneously, meaning there will always be low or negative pressure somewhere in the pressure zone.

During the time it takes for the pump to get up to full speed, two related but different phenomena are occurring.

- The first phenomenon occurs when customers at low elevations continue to use water and leaks will persist. Why? When a customer at a lower elevation opens a faucet while customer at a higher elevation has an opens faucet, air is sucked into the system to replace the water that is flowing out.

- The second phenomenon occurs when the pump initially shuts down quickly. A low-pressure transient wave moves through the system and reduces pressure even lower than one would expect in item one above. If the negative wave is sufficiently large, I’ve even documented negative pressures occurring in a system with elevated storage.

Why care about a short period of time where a few customers lose water service? Pressure back pretty quickly and doesn’t cause the customer much trouble.

The problem is that, when the pressure drops below that of the surrounding environment, intrusion of other whatever fluid that surrounds the pipe is drawn into the water system. In some cases, that fluid may be water that has just leaked out of the pipe and is still pretty clean. Conversely, that fluid might be sewage, chemical or biological waste, or anything else that might be in the soil which is why there are requirements for separation between water and sewer systems.

Even worse, if there are cross connections in a plumbing system not protected by backflow prevention, all sorts of fluids can be drawn into the distribution system whenever the pressure in the pipe is lower than the pressure in the non-potable source (for example, medical waste from a hospital or a vat of pesticide from a chemical plant.)

While it is not possible to perfectly protect a water system from a power outage, there are a few things that can be done to prevent or mitigate damage from depressurization.

- In systems without storage, a generator is essential, but even then, it does not provide perfect protection against low pressure.

- Since these events are short-lived, a small hydropneumatic tank can keep the system pressurized as the pumps are restarted. However, because the pumps in these zones are never shut off completely, water in the tank can get stale and lose disinfectant residual. In this case, the tank will periodically need to be drained and refilled with fresh water.

- An emergency control valve from a higher-pressure zone can be installed to bring water from that zone. In some cases, if suction pressure to the pump station is sufficiently high, water from the suction-side zone can be brought into the zone of interest through a check valve.

- The pump station can have a second power supply from a portion of the electrical grid that is somewhat independent from the main power supply. This can work when the power outage only affects the main power supply but not the secondary feed.

Want more information on this topic? Two individuals who have done a lot of work in this area Jian Yang and Mark LeChevalier from American Water. (Mark has since retired and does consulting under the name, Dr. Water.) I was fortunate to have worked with them on the chapter called Management of Low Pressure, AWWA Manual, M68 – Water Quality in Distribution Systems. The chapter is 37 pages and does a good job summarizing the state-of-the-art in this area. The chapter also lists five pages of references for those wanting to take a deeper dive into this problem.

Additionally, hydraulic models like Bentley’s OpenFlows WaterGEMS, OpenFlows WaterCAD and OpenFlows HAMMER can be very helpful in identifying problems that will occur during a power outage. For example, a pump station can be turned off in the model and the effects can be simulated to determine the extent of low or negative pressure. The default type of model run is demand-driven, which means that demands are met regardless of pressure. Demand-driven results would be misleading if pressures drop substantially to the point that demands are impacted. In this scenario, it is important to select Pressure Dependent Demands (PDD) in the calculation options when making model runs. With PDD, demands met are adjusted based on pressure in each node of the distribution system.

In a system with an elevated or hydropneumatic tank, it’s possible to watch pressures in the system (and demand) drop as the water level in the tank drops. This will provide useful information about who will lose water service and when it will occur.

For zones with no storage or connection to a pressure zone with water, the only water that is delivered is water for customers at low elevations coming from draining pipes at higher elevations. In a model, the water in the buried pipes can be approximated by a tall skinny tank connected to a low point in the system. The top water level in the tank corresponds to the pipe at the highest elevation while the bottom water level corresponds to the elevation of the lowest pipe. To determine the diameter of this equivalent tank, calculate the volume of water in the buried pipes and use that value to calculate the diameter of the tank. Set up an Extended Period Simulation (EPS) run and watch the water level in the tank drop along with the pressure and demand supplied at each node. Admittedly, this is a crude approximation, but it will provide a rough estimate of who will lose water and when. You’ll need to ignore a lot of User Notifications because hydraulic models weren’t built to simulate draining a system.

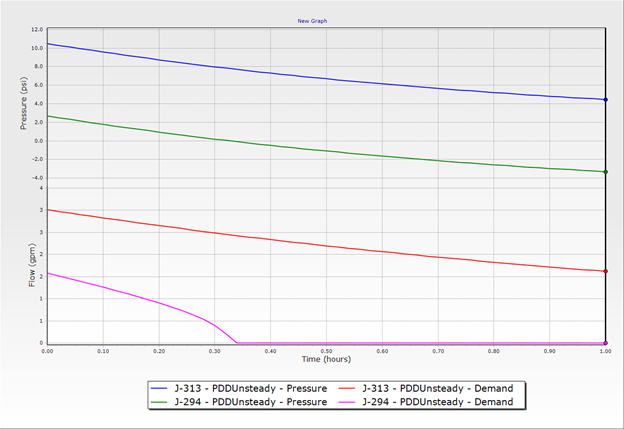

It’s possible to generate graphs. This particular one shows that for node J-294, when the pressure reaches zero (green line), the demand delivered also goes to zero (magenta line). But, for node J-313 at a lower elevation, some water may be delivered in small amounts (red line) and at low pressure (blue line).

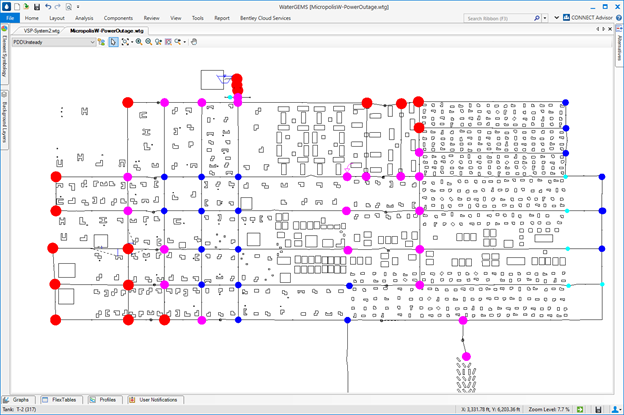

Another way to view these results is to color code the results by pressure, run an animation, (Times – Play) and watch the colors change as the system drains. Red nodes are out of water while blue nodes at the lower elevation, still have some water.

Your hydraulic model can help in identifying potential problem areas, planning to mitigate the problems, analyze what is occurring in near-realtime and review what happened in past power outages.

Want to learn more from our resident water and wastewater expert? Join the Dr. Tom Walski Newsletter today!