- Tom Walski, Ph.D., P.E.

- Senior Product Manager

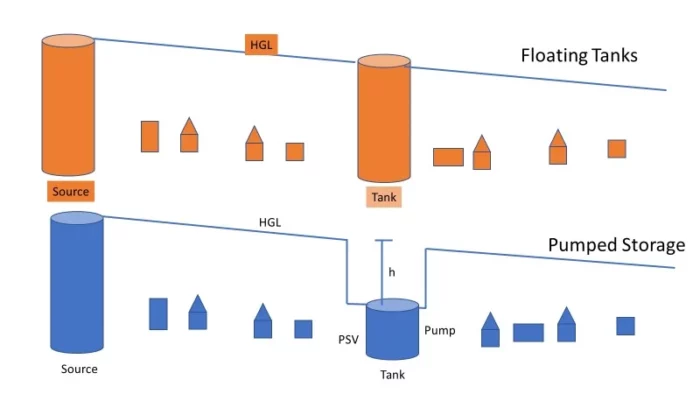

In most water systems, the tank water levels “float on the system” (orange system in the profile below). The HGL in the tank is the same as the nominal hydraulic grade in the system.

But in some cases, a storage tank in a pressure zone cannot be constructed to float on the system. The water that fills the tank must be pumped to the customers. Some examples of this are tanks:

- In an extremely cold area that would require heating (think Edmonton in the winter).

- On a flight path to airports (I’d rather not have an elevated tank at the end of a runway).

- So large as to be prohibitively expensive to build (ever see a 30 MG elevated tank?)

- That residents may not want to look at (not in my backyard).

Some of these reasons for pumped storage are more valid than others.

The downside of “pumped storage” comes from the word “pumped.” Water must be pumped out of the tank, and there is a cost for the energy to get the water back into the system.

The amount of energy wasted by pumping the water back into the system depends primarily on how far the water level in the tank is below the desired hydraulic grade (i.e., h in the figure above).

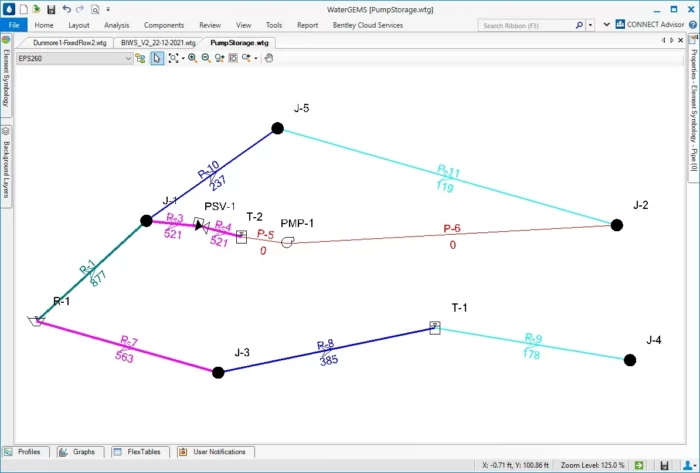

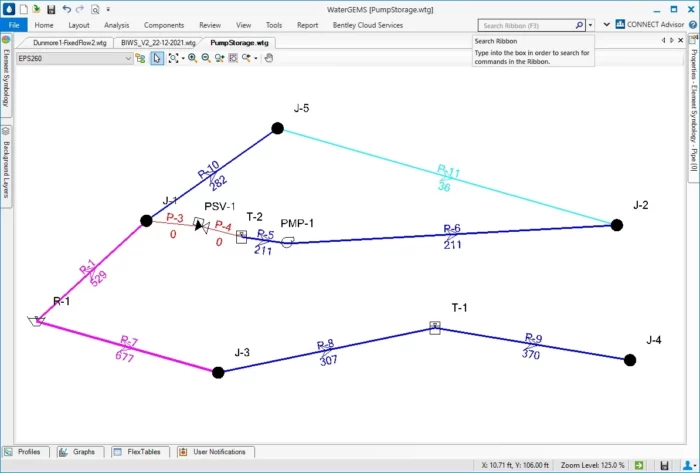

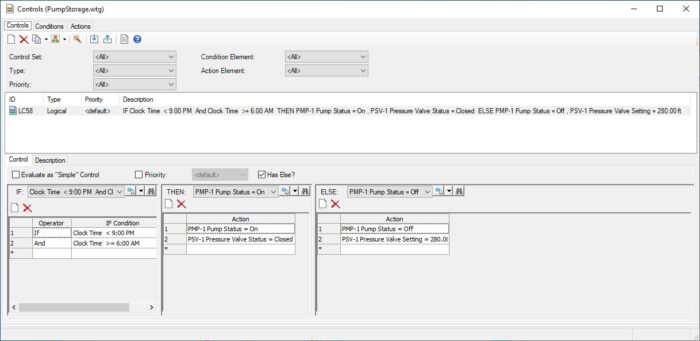

I built a schematic model with a pumped storage tank and pump. The nominal HGL was 300 ft, and demands were 600 gpm average. All nodes had the same pattern. It’s important to have a pressure sustaining valve on the fill line, or the pressure will drop to unacceptable levels near the tank when it is filling. The tank is filling from 9 pm to 6 am, and water is being pumped from the tank from 6 am to 9 pm. (There is also a floating tank on a parallel line that I used to make sure the performance in terms of pressure was very close.)

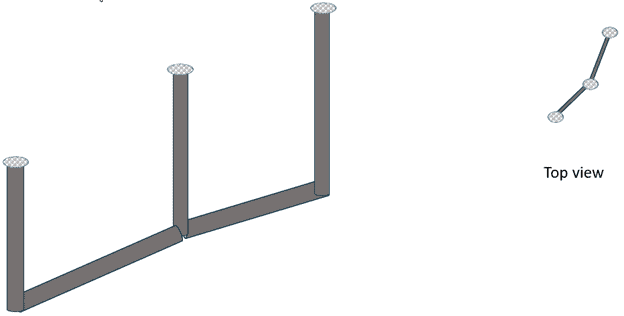

The figure below shows the flows when the tank is filling.

While the next shows the flow when the pump is running. (The flows are not identical because they are taken at different times of the day.)

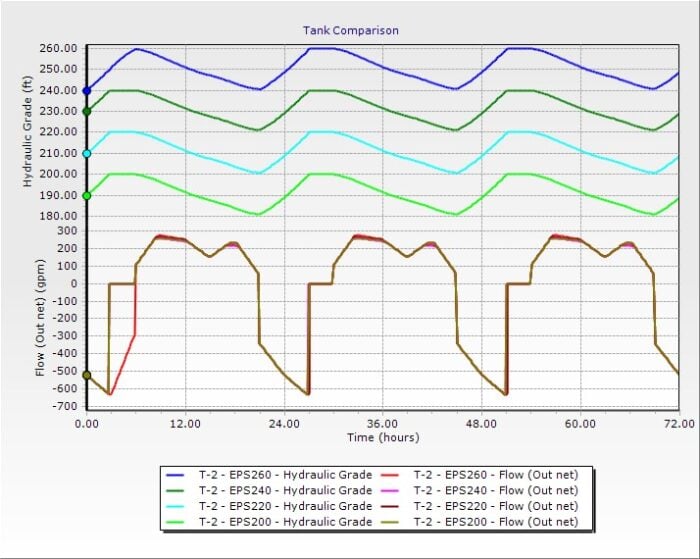

The ground level at the tank is 200 ft, and I set up OpenFlows WaterGEMS scenarios at 260, 240, 220, and 200 (buried tank) ft. I created a single control statement that could handle pump and valve operation across all four scenarios. The OpenFlows WaterGEMS user interface for this worked really well.

Here’s is what the HGL in the tank and flow out of the tank look like over a three-day period.

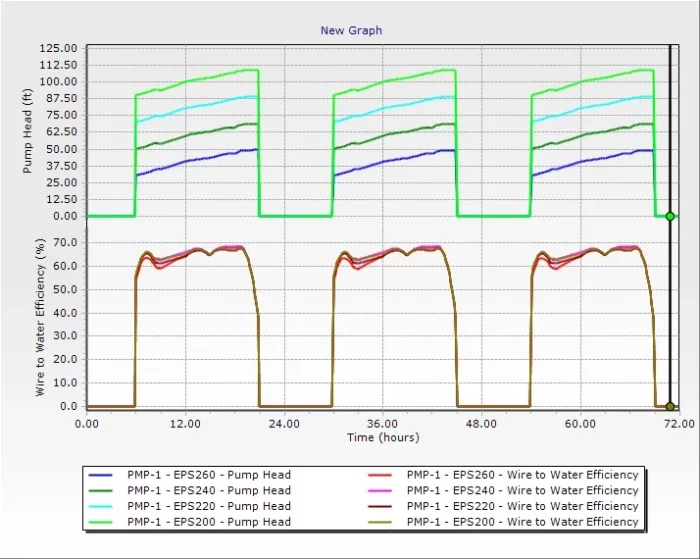

Here is a graph showing the pump head and efficiency over the four different tank configurations. The efficiency stayed pretty constant, which shows I’ve got the right pumps. The head the pump is required to produce increases, and the tank elevation drops.

The combination of OpenFlow WaterGEMS’ scenario manager and graphing made this work incredibly easy. I would hate to try this with any other software.

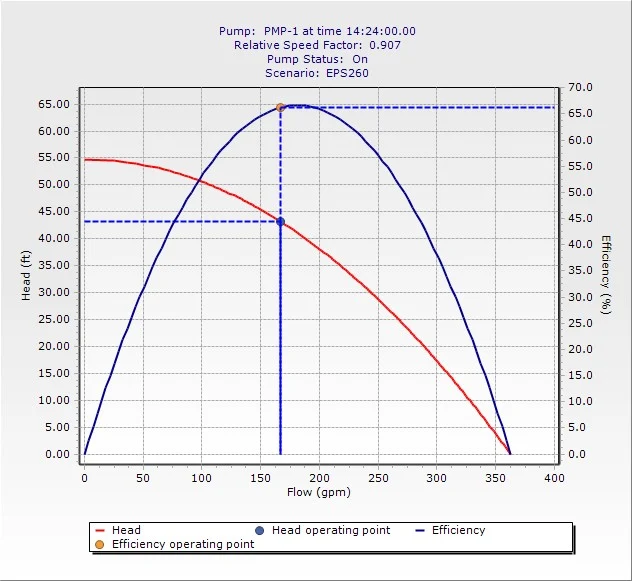

I also like the pump curve results to help me check operating points. All of the graphs were done within OpenFlows WaterGEMS. I didn’t need to export to Excel or use any other software.

Pumping costs can be minimized by not pumping much water from the tank and only using the pumps for peak periods. While this minimizes energy cost, it maximizes the water age and associated water quality problems. OpenFlows WaterGEMS lets users view the tradeoffs between water quality and energy conservation.

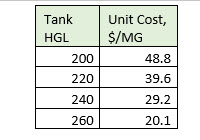

OpenFlows WaterGEMS’ energy costing feature was able to prepare a variety of tables and graphs for each scenario ranging from an overall summary like this table to a highly detailed report. For this analysis, the key result was the unit cost of energy in $/MG for each tank configuration, showing how much pumped storage was costing the system.

Of course, there are tradeoffs between the cost of an elevated vs. ground tank, especially in flat terrain, and the construction and maintenance cost of the pump station. But the most tedious calculation is energy cost, and OpenFlows WaterGEMS makes that easy.

If you want to look up past blogs, go to https://blog.bentley.com/category/hydraulics-and-hydrology/. And if you want to contact me (Tom), you can email tom.walski@bentley.com.

Want to learn more from our resident water and wastewater expert? Join the Dr. Tom Walski Newsletter today!