Welcome back for the second part of our “Real World Design” in hydraulics and hydrology! In the first part, we covered types of system design and sources of funding. Check it out here if you missed it!

Right-of-Way Considerations

The exact right-of-way for a pipe or land acquisition for a tank or pump station is not generally considered in explicitly in master planning but can have a significant effect on costs. Costs can vary dramatically and are not simply a function of diameter. Over a reasonable range of pipe sizes, the effects of laying condition far outweigh the effect of pipe size in determining cost.

There are numerous factors other than diameter that determine cost, including

- Paving

- Conflicts with other buried utilities

- Rock excavation

- Land ownership/easements

- Borings

- Stream crossings

- Environmental concerns

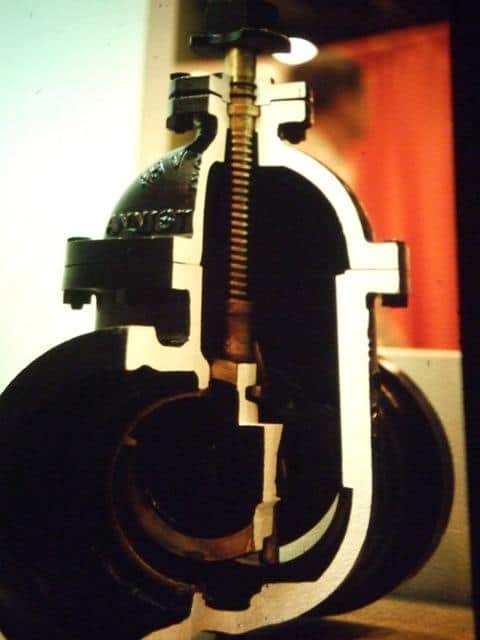

- Appurtenances (e.g., valves, hydrants)

- Tie-ins

Each of these considerations can dramatically affect the cost of a project. For example, a pipe may be laid along the east side of a road to avoid conflicts with other buried utilities. However, this means that it must cross an interstate highway off-ramp and the highway department will not give the water utility permission to shut down the ramp. Therefore, the utility must use boring equipment to drill under the road at a significantly higher cost than open trench pipe laying.

Pipes are laid in public rights-of-ways or across private land and the nature of the landowner has a huge effect on cost. The cost of pipe laying can vary widely from a route dealing with one owner versus another. The author has generally found that landowners/surface activity can roughly be ranked in inverse cost and difficulty with the list below.

- Railroads

- Department of Transportation

- Environmentally sensitive areas

- Stream crossings

- City streets

- Cross-country routes

- Street reconstruction/repaving

- New streets

Owners such as railroads and highway departments can require water utilities to obtain an occupancy permit to work in their right-of-way. These permits can require utilities to accept fairly costly procedures with regard to safety, signage, and restoration after construction. At the other extreme, when installation in a new subdivision before paving is done, excavation is trivial, connections to customers are easy, and paving costs are borne by others.

When working in existing streets, a major consideration is coordination with street repaving and other utility work. Dramatic cost savings in construction can be achieved if they can be coordinated with street repaving or sewer improvements. One of the worst things a water utility can do both in terms of cost and public relations is tear up a newly paved street to install water improvements.

Phasing Considerations

While master plans generally show the size and location of facilities, they do not always give the exact date of construction and even if they did, the date would be an estimate based on the accuracy of the forecasts used and budgetary/financial considerations. No utility can afford to install all the facilities identified in the master plan at time zero. Instead, construction must be sequenced over a series of phases that manifest themselves in the capital plan. The advantage of phasing of construction is that it enables the engineer to observe how earlier phases of the work have performed before constructing the next phase. They enable the engineer to make adjustments in capacity depending on how well the actual demands matched those that were used in developing the master plan. If growth exceeds projections, later phases can be accelerated or upsized. If they fell short of projections, they can be deferred or downsized.

Phasing isn’t usually important for small land development projects since developers usually plan to reach full build out quickly. On the other hand, facilities designed for long term planning may not be fully utilized in the early years of the project life. Sewers may not have sufficient flow to reach scouring velocity, water tanks and pipes may be so large that excessive disinfectant decay becomes problematic or pumps may run at inefficient operating points. While some of these problems tend to be resolved as the system builds out, some consideration needs to be given to operations in the early years.

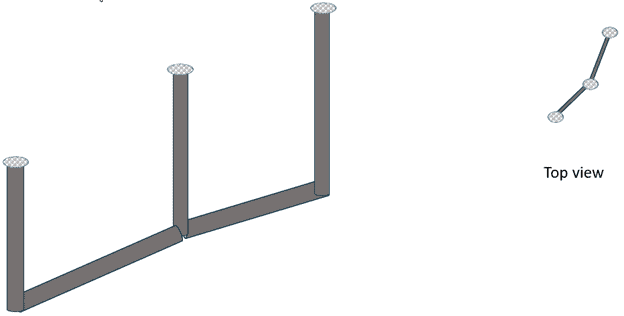

Conflicts

In planning studies, little consideration is given to other buried utilities. But in the final design, conflicts with other buried utilities become critical. Especially in urban areas, there may already be a myriad of storm and sanitary sewers, other water mains and laterals, electrical cables, phone and fiber optic cables, gas pipes, district heating and cooling lines and whatever else the city decide would best be left buried.

With pressure pipes, it is possible to run the mains over and under obstructions, but with gravity sewers, it is important to maintain a constant slope. Often, sewers are the deepest pipes and may be placed under the other utilities, although it may be necessary to relocate other utilities to avoid conflicts. In other cases, boring or directional drilling may be necessary. Clash detection, as done in Bentley’s Open Roads Designer, can be very helpful in avoiding these problems.

System Design Affects Demands

Another complicating factor in water system design is the assumption that future demand completely determines pipe size and location. While this is generally true, pipe capacity and location have the effect of driving demand to locations where capacity is available as a “self-fulfilling prophecy”. Consider a land developer who can choose from two sites: one with a large transmission main and one far from any water main. The site with water service is much more likely to be developed than the site which needs a substantial investment to provide water. The fact that pipe size and capacity have a significant effect on demand is difficult to measure and is generally ignored in planning, even though water system capacity influences growth. As the quote from the movie goes, “If you build it, they will come.” There is some truth to that.

Summary

While hydraulic design is the key to water distribution system planning, there are many other considerations that practicing engineers must take into account when designing a water system.

Want to learn more from our resident water and wastewater expert?

Join the Dr. Tom Walski Newsletter today!