We can agree that hydraulic models of water and wastewater systems are valuable tools. They are important in addressing master planning studies, system extension, rehabilitation, pump selection, and many other planning and design problems. In recent years, models have become increasingly important in solving real-time operations and maintenance problems. This opens new challenges for modelers.

In many cases, the modeler can simply grab the latest calibrated model from the master planning study and apply it to address an operational problem. However, water and wastewater systems are constantly evolving as new facilities are brought online, customers are added, or adjustments are made to system operations. Some of these changes have a negligible impact on system hydraulics while others dramatically change performance. For example, the old model from the master plan may not be as accurate of a representation of the real system as it once was. Or operators can’t wait until the next master planning study to update their model. However, real-time decisions need to be based on models of the system as it stands today.

Using an old model to operate your system is like using a road map from 1980 to find a route to a new location. The map may still be perfectly accurate, or you may end up at a dead-end miles from your destination.

A real-time model is only as useful to the extent that it reflects the current system. Adding a new tank, adjusting pressure zone boundaries, installing a new transmission main, or serving a new large customer can affect the calibration of the model. Unfortunately, keeping the model up to date doesn’t happen magically. A qualified modeler needs to initiate the steps to keep the model up to date.

The best time to update a model is when a new major facility comes online. These are facilities that change the hydraulics of the system (i.e., not a new 6-inch pipe in the back of a subdivision, but a 24-inch pipe from the main pump station). Bentley’s OpenFlows WaterGEMS and OpenFlows SewerGEMS provide ways to update model features using the Snapshot tool within ModelBuilder. This tool compares changes that have been made in the source GIS with the previous model to see what has changed. The modeler can then decide whether or not to bring those changes into the model.

Demands don’t change quickly so frequent updates to demands and patterns are usually not needed. However, if demands vary dramatically between seasons, or on weekdays compared to weekends, it is advisable to create different demand alternatives from which the best alternative can be selected at run time. OpenFlows WaterSight provides tools to use recent historical demands to identify patterns.

Changes in facilities and demand may also require modifications in operational controls so that changes in pump and valve operation can respond to the real system.

There is no single optimal frequency for model updates. The timing of updates has more to do with the timing of facility startup than any calendar date or pre-determined frequency.

There is also no simple answer as to who should update the model. A water utility that has dedicated individuals who focus on modeling may want to do the updates in-house. Those with smaller engineering staff or who had a consultant create the model may want to rely on the consultant for model updates.

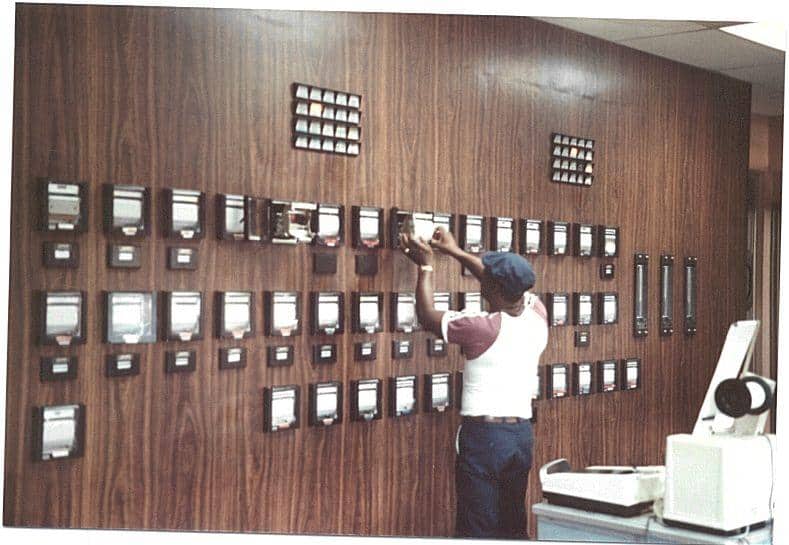

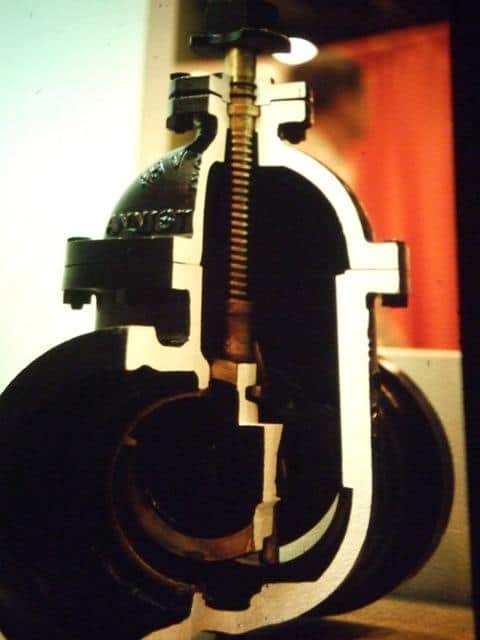

If the changes to the system and the model are substantial, this is a good opportunity to analyze the impact of the new facilities on the system. This doesn’t require a full-blown calibration study. Analysis can be accomplished by comparing model results with SCADA data or conducting some fire hydrant flow tests in the vicinity of the improvements to verify that the improvements are doing their job and that the model reflects those improvements. For example, it’s not uncommon that during a construction project, someone leaves a gate valve closed and this is a great opportunity to find those valves

The key is not to wait for an emergency to get started with real-time modeling. It’s actually having the model ready, like a fire truck prepared to go at a moment’s notice. That will enable the model to contribute to emergency response without hesitation. Overall, a model that reflects the current status of the system is what enables the next master planning exercise to get off to a better start rather than creating a new model from scratch or figuring out why the model doesn’t look quite right.

Want to learn more from our resident water and wastewater expert? Join the Dr. Tom Walski Newsletter today!