Dewatering network

Process pond fill

Project

Roy Hill Iron Ore is developing an AUD 10 billion, 55 million tonne-per-annum open pit, bulk mining operation in Western Australia. The massive project includes water supply and dewatering operations that cover 300 square kilometers. Roy Hill plans to reduce costs over the 20-year life of mine (LOM) by optimizing the design and operation of the integrated water network. This AUD 500 million initiative will provide water infrastructure that can rapidly adapt to expanding mining operations.

Solution

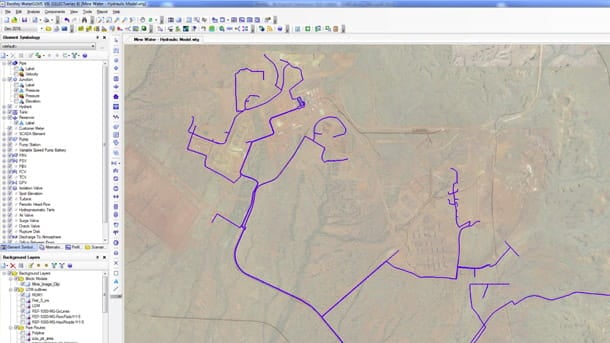

The water management team supplies variable quantities of water to consumer locations while preserving the limited groundwater. A WaterGEMS hydraulic model informs all planning and design decisions. By modeling current and future scenarios, the team optimizes pipeline sizes, pressure ratings, bore pump run time, and other factors to meet changing operational requirements at minimal cost. The team avoids delaying mining operations, keeping the site water table at least 1 meter below the pit floor.

Outcome

The optimized network has saved more than AUD 1.75 million—largely in capital expenditures (CAPEX)—within the first two years of operations. Over the life of the project, Roy Hill expects savings in capital and operating expenditures to total AUD 38 million. With 138 raw and 75 saline bores pumping 140 million liters per day during peak operations, the water management team is able to meet variable consumer demands, preserve groundwater quality, and fulfill dewatering and dust suppression objectives while minimizing surplus water disposal.

Software

The WaterGEMS hydraulic model contains both constructed and to be constructed items in the field. By looking at current and future scenarios and running extended period simulations in the hydraulic model, the project team can gain a better understanding of the system operation, answering some of the unknowns and removing an element of conservatism from the design process, thereby reducing the overall cost per project. For example, identifying and eliminating inefficiencies has reduced operational expenses, such as the amount of energy and number of bore pumps required to maintain supply tank levels.

Facts

- Reducing operating pressure allowed the use of smaller PN 6.3 or PN 8 pipes in 80 percent of the system, saving AUD 1.6 million within two years and AUD 16 million LOM.

- Reducing water supply bore run time reduced fuel use by 20 percent, saving AUD 2.4 million LOM.

- Reducing pump motor and genset size has saved AUD 1 million to date and AUD 10 million LOM.

- WaterGEMS ensures mining operations are uninterrupted by enabling rapid turnaround on changing water supply and dewatering operation plans.

“Bentley’s WaterGEMS software is the cornerstone to successfully delivering an evolving, effective, efficient, and flexible dewatering and water supply system for the Roy Hill mine site.”

“Bentley’s WaterGEMS software is the cornerstone to successfully delivering an evolving, effective, efficient, and flexible dewatering and water supply system for the Roy Hill mine site.”

Simon Windsor

Superintendent, Water Infrastructure

Roy Hill Iron Ore