Saving energy is a multi-faceted problem and there is not a single solution. There are plenty of ways of wasting energy and it takes some analysis to determine WHY energy is being wasted before moving on to HOW can you save energy.

Find that wasted energy in your system

A problem with energy studies is that a pump won’t tell you it’s wasting energy. An inefficient pump looks, sounds, feels, smells and probably tastes just like an efficient pump. It’s not going to shout, “Hey, look at me. I’m robbing you blind.” Instead, the engineer/operator needs to apply technology to find those bad actors. Walking into a pump station is like walking into a gold mine. There are nuggets of gold (energy) lying around but you need to do a bit of digging to find them.

There is a certain amount of detective work in determining how pumps are wasting energy and there is a logical procedure for going through the large amounts of data that provide clues to pump problems.

Determine the WHY energy is being wasted

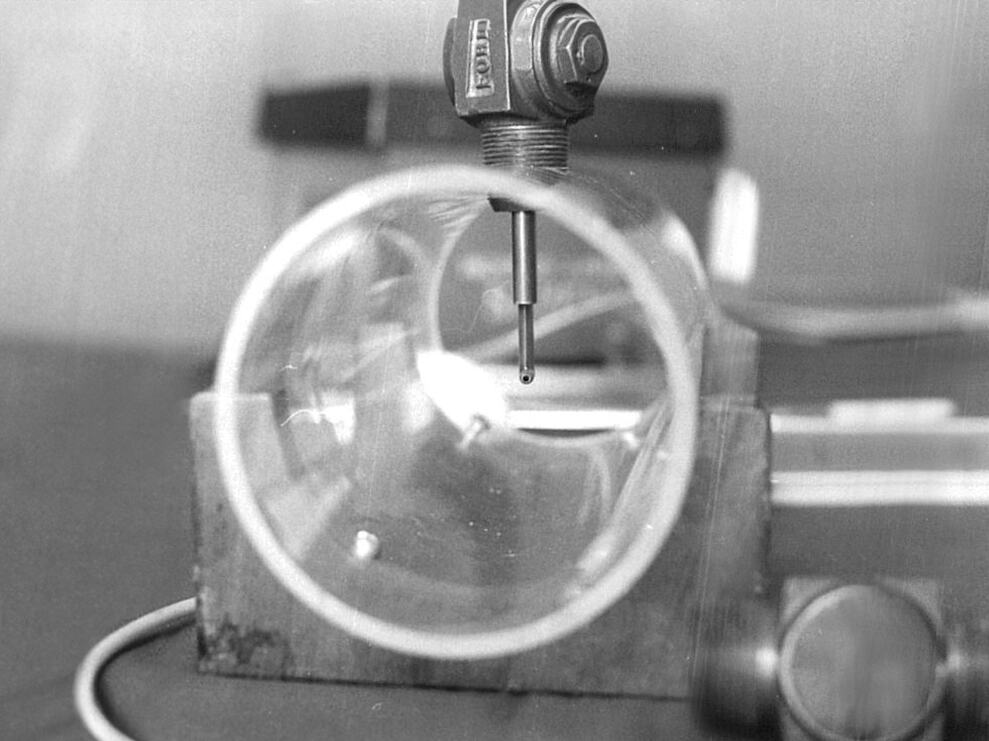

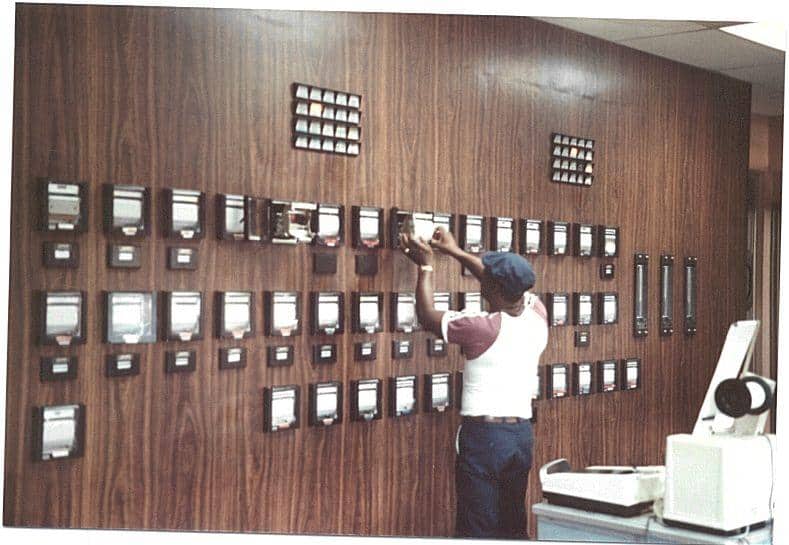

It’s best to start with the individual pumps and use SCADA (Supervisory Control and Data Acquisition) and pump test data to determine the flow, head and energy use. Check to make sure the pump is operating at or near its best efficiency point (BEP). Of course, to do that you need to find the pump curves for the pump. The curves should be readily available but sometimes finding them takes some detective work itself.

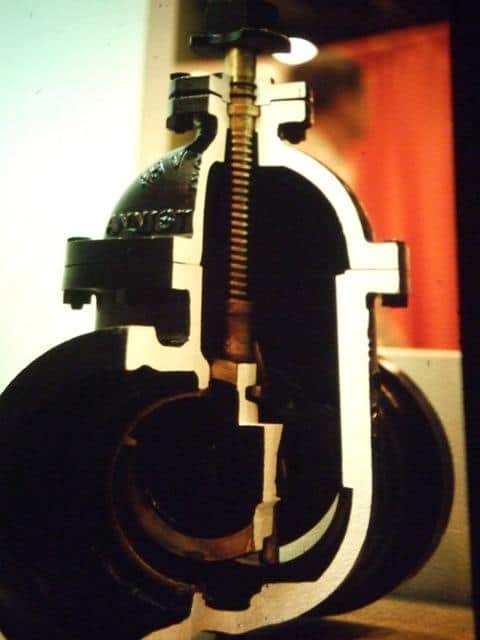

If the pumps are not operating on the right curve at their BEP, determine why that is occurring. Is it a mechanical problem with the pump (worn bearings, misadjusted clearances, damaged impeller)? Or does the pump not match the system correctly (system may have changed, a closed valve near the pump)?

Understand the HOW you can save energy

Your OpenFlows WaterGEMS model should show you where the pump should be operating on the curve and give you clues when it’s not operating there. Sometimes, the fix is as simple as setting the clearances or opening a closed valve.

In some cases, there is a problem with the pump, and it needs repair or replacing. WaterGEMS can determine the energy savings from replacing a pump. Maybe the pump needs a new higher efficiency motor or possibly the system has changed so much that the old pump doesn’t match the system requirements any longer. If so, then you need to find a replacement pump.

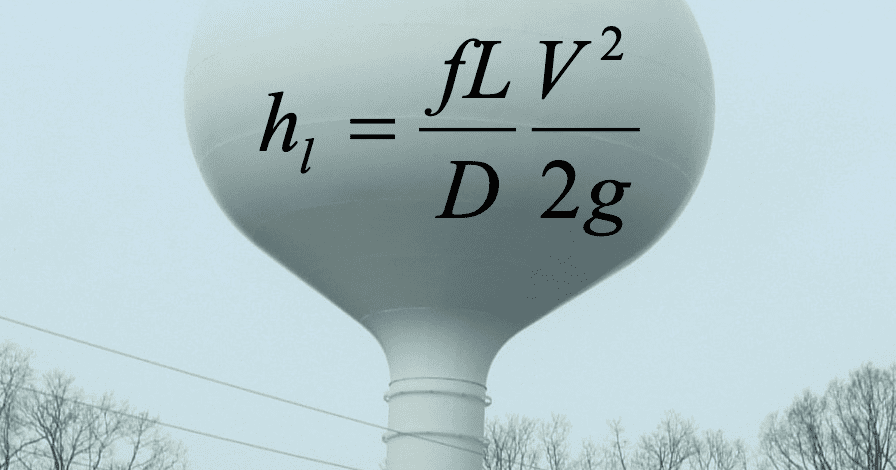

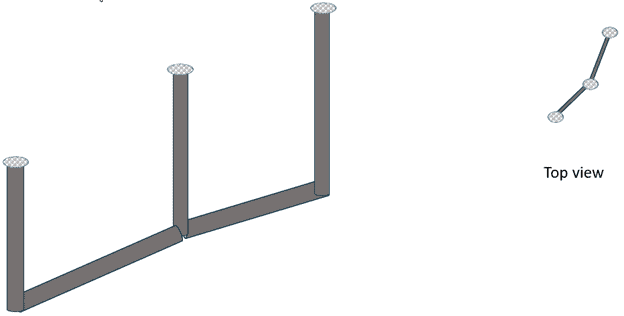

Replacing a pump (or specifying a pump for a new pump station) requires determining the system demand, developing the system head curve, trying different pumps until you find one that matches the system over a wide range of conditions, calculating the life cycle costs, checking how the pumps operate alone and in combination with others and establishing controls for operations. WaterGEMS can help with virtually all of these steps. Simple specifying a duty point flow and head may not get you the best pump.

The next question is whether to select constant speed or variable speed pumps. Variable speed pumps sound great, and they are promoted as energy savers. In some water and wastewater cases, they are, but in others, they actually waste energy. WaterGEMS can perform the calculations to make the comparison.

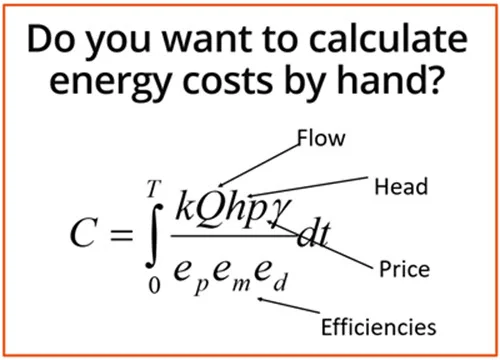

Wasted energy cost is not all about the pump but also about the tariff that converts pump usage into costs. If you haven’t reviewed the power company’s tariff document, first try to find it, and once you do, figure out the formula the power company uses to bill the water company. Warning, it’s not as simple as kilowatt hours times cents per kilowatt hour. Time-of-day pricing and peak demand charges are a few of the ways, that energy pricing can be tricky.

Then there are the actual energy bills. How many engineers/operators actually review their energy bills? Even with efficient pumps, you may find ways that the power company is making more money from the water utility than necessary. But you need to look for these nuggets of gold.

Pump operations can also have an impact on energy cost. While you need to pump a certain volume each day to meet demands, some operating strategies are better than others and your model can help you find them.

A comprehensive energy study is an important step in finding those problems, but some resources need to be directed into those efforts. Upper managers say they want to save energy, but so often, these analyses and put on the back burner as utilities struggle with everyday issues. Customers and regulators aren’t calling the water and sewer utilities and complaining about how much money the utility is spending on energy. So, energy wasting goes along quietly. Meanwhile, a bad pump won’t heal itself. A commitment must be made to reduce energy costs.

By using WaterGEMS and SCADA data, you can be a good detective, and find and arrest the energy thieves in your system. The payback from analyzing energy usage comes quickly and persists in the operating budget for a long time.

Want to learn more from our resident water and wastewater expert? Join the Dr. Tom Walski Newsletter today!