Virtuosity Blog

A New Bridge, A New Tool…A Lifecycle Process Improvement

Shifting to a new design software is not always easy, particularly while immersed in an already challenging project.

However, while working on a project in Arizona, we saw an opportunity to use the features and functionality of a new solution to solve a challenging problem…and advance the industry workflows. We first heard about OpenBridge Designer, about a year ago and believed it could take us to the next level of 3D design and analysis. That said, adapting to a new software, workspace, library, workflow, and technical support are always big concerns—but we believed the positive outcomes would outweigh any potential learning curves.

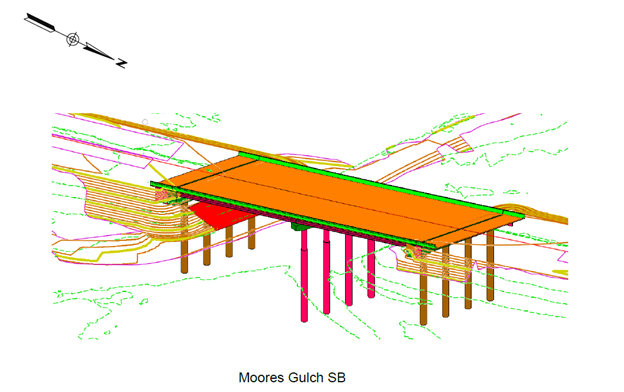

The Arizona Department of Transportation (ADOT) I-17 Anthem Way Improvement Project proved to be an ideal testing ground. I-17 is the only direct route connecting the Phoenix area with northern Arizona and the mountainous, federal forestland that flanks the highway offers no reasonable alternate routes. The improvement will help address the congestion and travel delays currently experienced along the corridor on weekends and holidays. A critical element of the project is the full replacement design of the Moores Gulch Bridge SB. The new bridge is a two-span prestressed concrete I-girder bridge with phased construction.

For the effort, we are required to submit the 3D bridge model in addition to the traditional plans in MicroStation . MicroStation has been our main software, not only because it is required by the client, but also because Bentley efficiently produces plans. We opted to use the OpenBridge Designer 3D modeling, analysis and design tool for this effort to hopefully simplify some design methods.

In the past, as bridge engineers, we spend a considerable amount of time coordinating with roadway engineers on geometry. But now with the dynamic alignment and terrain in OpenBridge Designer I can easily capture all the geometry information I need for bridge design. Further, with our dynamic bridge model, the roadway engineer is able to adjust the profile, alignment, and grading based on the bridge model as necessary.

As well, we were able to learn new capabilities. For instance, during the design, we wanted to create a parametric cell for the abutment cap. It’s a task that can be challenging. However, with all the built-in modeler and learning videos, OpenBridge Designer proved to be satisfactory for this task. It took me a week to learn how to create parametric cells, and about three days to generate the entire bridge model. Overall, with the OpenBridge Designer model, each department has a better understanding of what we are doing, which cuts out a lot of time in explaining and coordination. Also, the 3D model is dynamic, which allows team members to see updates in real-time.

Currently, we are in a transition from MicroStation to the OpenBridge Designer We still have a lot to learn to establish a workflow standard to cut the time of modeling—but we’re making progress. I believe future contactors will build our bridges without 2D plans and instead with the full vision of the 3D model via laptop or iPad. Technology such as OpenBridge Designer will help us fulfill that vision.

About Anson Ouyang: Mr. Ouyang is a bridge engineer with nine-years experience working at TYLin. He graduated from New Mexico State University with B.S. and M.S. of Civil Engineering. He started his bridge career after graduate school by analyzing bridge load ratings and researching bridge design. Mr. Ouyang is now responsible for the bridge design, plan production, and mentoring young engineers. He loves to adopt new technology and software. He has been developing the new design workflow to accelerate and simplify the traditional design method with more efficiency and accuracy. Excel VBA, LARSA 4D, and OpenBridge Designer are his favorite tools.

Mr. Ouyang is a bridge engineer with nine-years experience working at TYLin. He graduated from New Mexico State University with B.S. and M.S. of Civil Engineering. He started his bridge career after graduate school by analyzing bridge load ratings and researching bridge design. Mr. Ouyang is now responsible for the bridge design, plan production, and mentoring young engineers. He loves to adopt new technology and software. He has been developing the new design workflow to accelerate and simplify the traditional design method with more efficiency and accuracy. Excel VBA, LARSA 4D, and OpenBridge Designer are his favorite tools.

About TYLin:

Founded in 1954, TYLin is a globally recognized, full-service infrastructure consulting firm committed to providing innovative, cost-effective, constructible designs for the global infrastructure market. With 3,200 employees working in 65 offices throughout the Americas, Asia, and Europe, the firm provides support on projects of varying size and complexity. TYLin is a member of Dar Group, a global, privately-owned professional services group, and its industry-leading family of Global Infrastructure companies